-

Up to 26% off

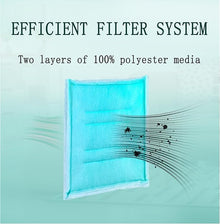

Up to 26% offSeries 55 Wet Tack Panels Intake Filter (MERV 7)

Regular price From $101.53Sale price From $101.53 Regular priceUnit price per$123.68 -

AR-1 Intake Panels and Links(MERV 8)

Regular price From $157.56Sale price From $157.56 Regular priceUnit price per -

Up to 19% off

Up to 19% offPaint Booth V-Pocket 1 Ply Dry Tack Intake and Exhaust Filter

Regular price From $177.37Sale price From $177.37 Regular priceUnit price per$219.56 -

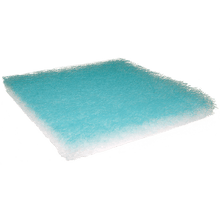

15Gram Fiberglass Paint Arrestor Pads

Regular price From $63.75Sale price From $63.75 Regular priceUnit price per -

Up to 21% off

Up to 21% off15Gram Fiberglass Paint Arrestor Rolls

Regular price From $75.00Sale price From $75.00 Regular priceUnit price per$84.36 -

18Gram Fiberglass Paint Arrestor Pads

Regular price From $69.68Sale price From $69.68 Regular priceUnit price per -

Up to 21% off

Up to 21% off18Gram Fiberglass Paint Arrestor Rolls

Regular price From $76.21Sale price From $76.21 Regular priceUnit price per$93.95 -

Up to 17% off

Up to 17% off22Gram Fiberglass Paint Arrestor Pads

Regular price From $88.25Sale price From $88.25 Regular priceUnit price per$104.50 -

Up to 5% off

Up to 5% off22Gram Fiberglass Paint Arrestor Rolls

Regular price From $103.89Sale price From $103.89 Regular priceUnit price per$109.00 -

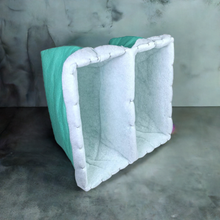

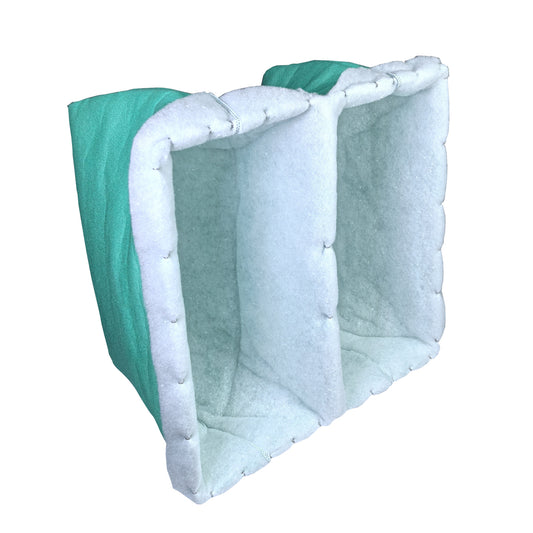

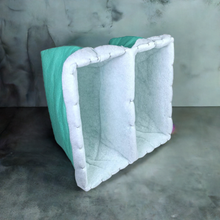

560-Intake Panels

Low stockRegular price $428.08Sale price $428.08 Regular priceUnit price per

Added to your cart